Features of the design of a step-chair, do-it-yourself manufacturing

In the household it is often necessary to do something at a height: nail a nail, get things off the top shelf or hang curtains. At the same time, the space in most apartments is limited; bulky stairs are nowhere to store. In this case, a great solution can be a step-chair, which differs little from the usual. If necessary, such a chair can be quickly expanded, it comes in different sizes and shapes, so it fits easily into any interior.

What is a

A transforming chair is a wooden product that looks like an ordinary chair, but can turn into a stepladder. The product has many advantages:

- takes up little space;

- does not require additional support, it is easy to move;

- able to withstand heavy weight, while maintaining stability;

- you can do it yourself at home with the help of improvised materials;

- easily transforms into a ladder.

The design of such a chair consists of the following parts:

- front, rear sidewalls;

- back straps;

- seat

- steps.

Such transformer chairs have been used in everyday life for a long time. Initially, they were used in libraries, as they made it easy to reach even the very top shelves. Soon after, the idea passed to the people, step-stools began to be found everywhere. At the same time, the appearance of the products can be completely different: the chair can be made of inexpensive wood or decorated with decorative and carved elements. It all depends on the imagination of the joiner.

Design Varieties

Before choosing or manufacturing the product, you need to determine the type of design. Do-it-yourself transformer stepladder chair can be made of various materials:

- Most often, a tree is chosen as the basis. It is cheap, durable and, if properly processed, can last for many years. In the hardware store you can buy different breeds. The most budget option is pine and birch. More expensive is oak.

- Plywood products are easier and cheaper, but are less durable. The maximum weight that they can withstand is 80 kilograms.

- Plastic step chairs are the most affordable. They can be found in most construction stores, and the price is only a few hundred rubles. However, their quality is poor, and their service life is limited.

- Metal stepladders are characterized by increased strength and can last for more than a dozen years. If you decide to purchase such a product, then it is better to choose a chair made of aluminum or stainless steel, since these materials are least susceptible to corrosion.

According to the type of design, the chairs are of several types.

- An ordinary step-chair is outwardly rather unpretentious and takes up a lot of space. Most often, such a product has one wide seat and 2-3 steps that can be extended or folded. This model can be used both in the kitchen and in the living room as a stool or even a bedside table.

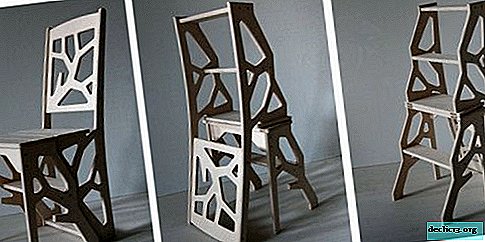

- Transforming chair - looks like an ordinary one, several steps are hidden in the lower part. Such a piece of furniture can easily be turned into a stepladder.

- Folding Stool - Designed for lifting to medium height. Sometimes equipped with a back. A stool in the form of a staircase is an excellent mobile option for small rooms.

- Step stool - uhthen a slightly different design. The product is usually made without a back and is equipped with several outgoing modules.

The design of the transformer chair can be folding or stationary. The first models take up less space, but the second is more reliable and stable. In addition, they can be used as a stand for objects or indoor flowers.

Step Chair

Step Chair Transformer chair

Transformer chair Folding Stool

Folding Stool  Step stool

Step stool Drawings and Dimensions

You can make a folding chair-ladder with your own hands or purchase a finished product in a store. True, its cost will be quite high at the same time, so many people prefer to make it on their own. The work is simple, ready-made drawings and diagrams will help even a novice to cope.

The design of the chair depends on the design and materials. First you need to decide on the purpose of using the product, based on this, the material and the necessary tools are selected. Making a drawing is not easy, it is best to use ready-made options. If you nevertheless decided to make the drawings yourself, then you need:

- determine the size of the product;

- properly design the structure;

- will take care of stability: if the chair is high, then it needs to be made wider.

For the drawing of a stepladder, take the average designations:

- Seat size - 40 x 50 cm.

- The width of the main unit should be at least 40 cm. But the larger this figure is, the more stable the product will be.

- The height of a folding step-stool is best done for a specific person. Usually it is about 60-70 cm.

- Steps (there should be at least three) are already made than the seat, about 15 cm.

The design must be carefully thought out during manufacture because unreliable fasteners or guides can cause further injury. As a material, experts recommend taking a solid wood 2 cm thick or plywood 1.5-2 cm.

DIY manufacturing steps

A folding stepladder can be made of wood with your own hands. Regardless of which product design needs to be manufactured, the following materials will be needed:

- a set of drills of different diameters;

- self-tapping screws, screws;

- pre-ground timber or plywood;

- drill;

- guides;

- loops.

Also, do not forget about the glue, varnishes and paint that will be needed for subsequent finishing.

Transformer chair

This version of the multifunctional chair is easy to use, but making it with your own hands from wood is not so simple. Pine or ash is suitable as a material, but plywood should not be used. To make a chair you will need the following details:

- two sidewalls: one for the footboard, the other for the chair itself;

- seat base;

- a rotary step, which when folded is a continuation of the seat and increases its width, making a full-fledged chair out of the stairs;

- backrest rails;

- steps.

After the drawing of the transformer stool is prepared and the tools are selected, you need to cut out the details from the tree, grind them. Start collecting stools by connecting the sidewall with steps and slats. After that, proceed with the assembly of the sliding part: a thorough step and a rotary step are screwed to the sidewall.

During operation, experts do not recommend using glue to fasten parts; a product assembled with it will not be durable.

Mark and chamfer milling at the bottom of the sidewall

Mark and chamfer milling at the bottom of the sidewall Cut inner sidewall contour

Cut inner sidewall contour  Cut the outside contour of the sidewall of the chair

Cut the outside contour of the sidewall of the chair  Transfer the drawing to the blank for the second sidewall of the chair

Transfer the drawing to the blank for the second sidewall of the chair  Repeat procedure with all four side parts of the chair

Repeat procedure with all four side parts of the chair The result is two pairs of blanks

The result is two pairs of blanks Grind the end parts of the sidewalls

Grind the end parts of the sidewalls Get rid of the sharp ends of the sidewalls using a milling cutter

Get rid of the sharp ends of the sidewalls using a milling cutter Using the same technology as the sidewalls, make the back of the chair

Using the same technology as the sidewalls, make the back of the chair Prepare parts for installation

Prepare parts for installation Glue and screw the middle step placed in the chamfer with screws

Glue and screw the middle step placed in the chamfer with screws Make a markup for the seat

Make a markup for the seat Attach the steps to the stepladder

Attach the steps to the stepladder Screw the seat

Screw the seat Coat all self-tapping screws with wood putty and sand the entire structure

Coat all self-tapping screws with wood putty and sand the entire structure 2 parts fasten together with a piano loop of the appropriate length

2 parts fasten together with a piano loop of the appropriate length It remains to paint the wooden structure in the desired color or just cover it with a protective agent

It remains to paint the wooden structure in the desired color or just cover it with a protective agent

Tall step stool

The stepladder stool is more durable, moreover, it is easier to make. The only minus is not a very attractive look, but this drawback can easily be corrected with the help of correctly selected materials and decor elements. For the manufacture of stools, the following details will be required:

- legs (4 pcs.);

- lower and upper crossbars (2 pcs.);

- steps (2 pcs.), the upper should be the widest;

- cross strips (4 pcs.);

- side walls for extendable, stationary part;

- base (1 pc.).

The stool can be made of plywood. After cutting out all the parts, it comes to assembly according to the following scheme:

- Connect the sidewalls and steps with brackets and cross bars.

- Collect the retractable part: fastening the bases, side, rear walls.

- A step is installed, the whole structure is fastened with screws.

A transformer stool is more stable if you cut the crossbars and steps at an angle of 75 degrees.

Step Stool Diagram

Step Stool Diagram The steps should be 44 cm wide and approximately 15 cm deep.

The steps should be 44 cm wide and approximately 15 cm deep. To make a seat, support rack, ladder, rails for connecting the structure

To make a seat, support rack, ladder, rails for connecting the structure Assemble seat

Assemble seat Prepare the support part for assembly

Prepare the support part for assembly All connections must be made with dowels.

All connections must be made with dowels. Then measure the location of the steps and make recesses using the milling cutter

Then measure the location of the steps and make recesses using the milling cutter Between the upper step and the seat, fix the rails for connecting the support pillar and the ladder with one end, and secure the second ends in the middle of the support pillars

Between the upper step and the seat, fix the rails for connecting the support pillar and the ladder with one end, and secure the second ends in the middle of the support pillars  Result

ResultLadder Chair

A ladder chair can be folding, but more often it is made stationary. To work, you will need to cut the following details:

- side ends (2 pcs.);

- crossbars (4 pcs.);

- drawers (3 pcs.).

The manufacturing process of the ladder chair is quite simple. Lateral parts and crossbeams fasten by means of self-tapping screws. The steps are screwed with the help of the tsar. This option of a wooden step-chair is very convenient in everyday life, it can be used not only as a ladder, but also as a shelf.

Drawing of a ladder to a finished stool

Drawing of a ladder to a finished stool Cut parts

Cut parts Glue all the elements of the step

Glue all the elements of the step Screw the parts to each other, and then the resulting structure to the stool

Screw the parts to each other, and then the resulting structure to the stool Result

ResultSpiral module stepladder

The following details will be required to create this model:

- 12 legs that can be made of the same diameter, different lengths. The highest part should be 82 cm, and the smallest - 32 cm.

- 3 steps with sizes: 40, 15, 20 cm.

The entire structure is assembled simply. Fasten the highest part of the chair, and attach the base with a width of 40 cm to the legs using self-tapping screws. Then proceed to the sliding part, namely, fasten it to the main.

Product Decor

In order for the stepladder to be not only functional, but also beautiful, it needs to be decorated. To do this, fit:

- paints;

- decoupage;

- carved decorative elements;

- application of aging technology.

Of course, for the transformer stool to serve for a long time and please the eye, the tree must first be sanded.

- If there is no special machine, then this can be done using the most ordinary sandpaper.

- Then you need to apply a thin layer to the surface of the soil, wait until it dries. If you want to preserve the natural color and structure of the tree, you can immediately coat the product with varnish. Then it remains only to choose a suitable color and paint the chair.

To keep the paint longer, experts recommend applying a layer of varnish on top of it.

Often, furniture designers perform the decoupage of a stepladder, because with it you can easily fit the product into the interior. For work, you need rice paper, acrylic paint, craquelure varnish.

- If the aging effect is chosen, then first you need to cover the transforming chair in the form of a ladder with metallic paint. It is better to use an aerosol can for this, which will evenly distribute the pigment.

- Then, the steps on which the drawing will be applied should be painted white.

- After that, rice paper with a suitable print needs to be applied to the surface and coated with PVA glue. It remains to wait until the steps dry out. Wipe the dried surface slightly with sandpaper to give an aged effect.

Transformer chairs will never go out of style thanks to their functionality. They can be used as furniture for construction work or as a design element. If you select and process the material correctly, the product will last for many years.